// DAC Technology

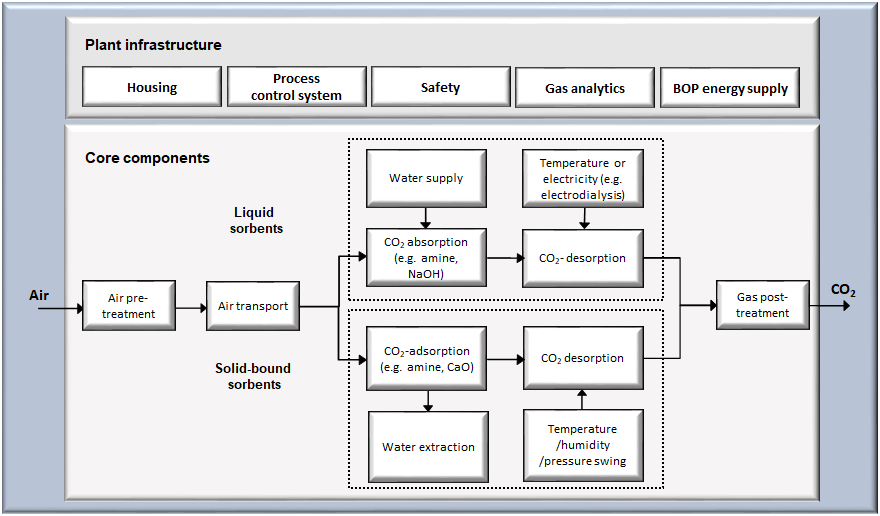

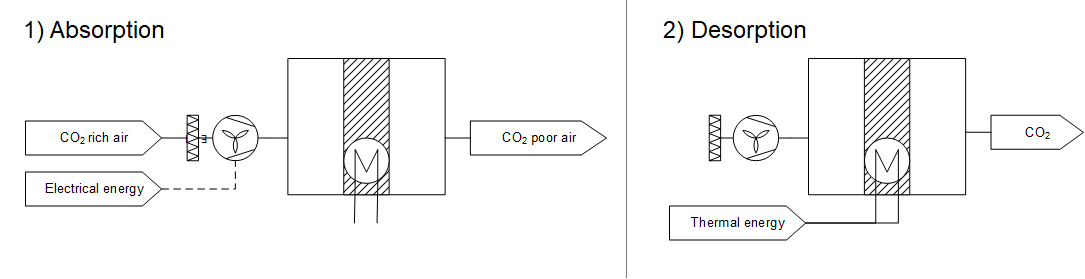

The direct separation of carbon dioxide from the air using apparatus is generally summarised under the acronym DAC, which stands for direct air capture. The general principle is to route air by means of fans through a filter material or sorbent which selectively separates the carbon dioxide through chemical or physical bonds (absorption or adsorption). When a defined CO2 concentration is reached, the filter material is saturated and must be regenerated by separating the accumulated carbon dioxide again (desorption). This is done in most cases by introducing thermal energy. The sorbent is then able to absorb CO2 again and the process goes back to the beginning.

The major challenge in extracting CO2 from air lies in the low concentration of the carbon dioxide of around 400 ppm, leading in turn to high airflow rates and, by association, high levels of energy input. It is therefore essential when selecting possible methods of CO2 capture to avoid changes in the airflow situation as far as possible, such as changes in temperature or pressure. The low CO2 concentration also means that there is a need for a sorbent with the highest possible selectivity in relation to carbon dioxide and one which is not discharged from the DAC system into the environment despite the high airflow rates.

DAC processes can basically be divided into high-temperature and low-temperature processes. High-temperature methods are based on alkaline potassium hydroxide or sodium hydroxide solutions as sorbents and work with desorption temperatures of around 900 °C whereas amine is used as the sorbent in low-temperature processes and the desorption temperature is only about 100 °C.

| Method | High-temperature process (liquid sorbent) | Low-temperature process (solid sorbent) | Low-temperature process (solid sorbent) | ZSW process (liquid sorbent) |

|---|---|---|---|---|

| Company | Carbon Engineering (Kanada) | Climeworks (Schweiz) | Global Thermostat (USA) | ZSW (Deutschland) |

| Desorption temperature | 900 °C | 100 °C | 85-95 °C | 100 °C |

The high-temperature method can take the form of a continuous process due to the aqueous sorbent but the low-temperature processes predominantly feature the use of solid amines and there is a general prevalence of batch operation because of their immobile nature.

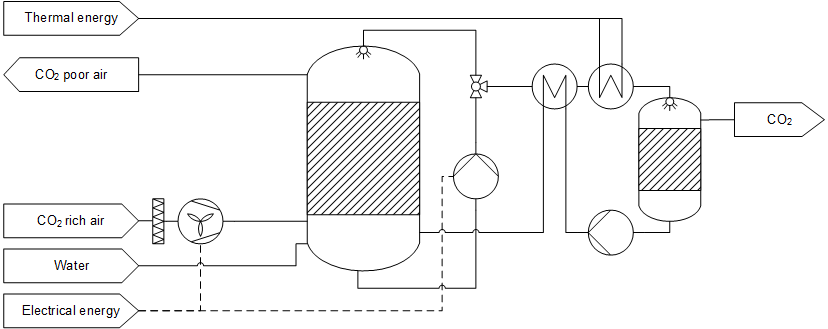

The diagram opposite illustrates the DAC process developed at the ZSW where an aqueous polyethyleneimine solution is routed counter to the air through an absorber acting as a gas scrubber, thereby also allowing continuous operation in the low-temperature range. A blower is used to force the air to flow in the reverse direction. A pollen filter installed in front of the fan prevents contaminants from entering the PEI solution. The surface forming a border between the scrubbing solution and air in the absorber itself is increased by a gasket or packing. The PEI solution enriched with CO2 is ready for the regeneration phase when it is pumped to the desorption unit where the CO2 is separated from the scrubbing solution at an elevated temperature. The CO2 is processed downstream while it is still wet, undergoing dehumidification in a condensation drying step. Now with a depleted CO2 concentration, the PEI solution is pumped back out of the desorption unit into the absorber where the process begins again.

Interior view of the 100 tCO2/a demonstrator at ZSW consisting of absorber (left) and desorber (right).